Schreiben Sie uns eine E-Mail :

info@labcompanion.cn-

-

Rückruf anfordern :

+86 18688888286

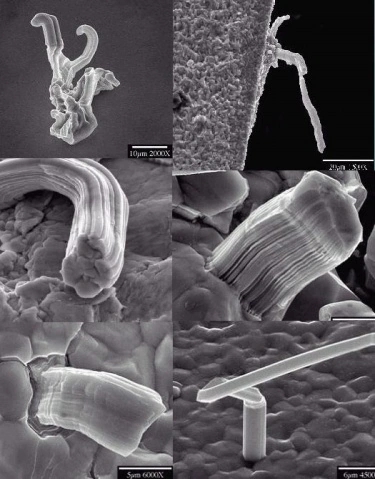

Bei der Herstellung bleifreier Komponenten wird zur Erhaltung der Lötbarkeit häufig eine reine Verzinnung anstelle des ursprünglichen Zinnbleis verwendet. Nach einiger Zeit bildet die reine Verzinnung dendritische, hervorstehende bei Raumtemperatur, genannt Zinnwhisker (Whisker). Zinnwhisker unterscheiden sich grundlegend von der Ionenwanderung. Zu lange Zinnwhisker können Kurzschlüsse zwischen Leitern oder Bauteilen verursachen. Derzeit wurden entsprechende Normen zur Zinnwhisker-Erkennung formuliert, und Umweltprüfmethoden für Zinnwhisker können Unternehmen dabei helfen, die Hemmmethode für Zinnwhisker zu testen. Die Methode zur Vermeidung von Zinnwhiskern erfüllt die Anforderungen und Normen für bleifreie Schwermetallprozesse. ist dringend in der hochverdichteten Bauweise von elektronischen Produkten (Mobiltelefone, PDA, MP3, Automobilelektronik etc.). Lab Companion LTD. hofft, Kunden beim Importieren von Zinnwhiskerntests so schnell wie möglich zu unterstützen, die Wettbewerbsfähigkeit des Unternehmens selbst zu steigern und zu stärken durch die Sammlung und Sortierung relevanter Informationen.

(1) Es gibt 13 Faktoren, die das Wachstum von Zinnwhiskern beeinflussen

1. Korngröße

2. Eigenspannung

3. Externer Stress

4. Organische Stoffe, einschließlich: Kohlenstoff, Schwefel, Sauerstoff usw.

5. Wasserstoff und Wasser sammeln sich

6. Thermische Belastung

7. Elektrische und magnetische Felder

8. Keimbildung

9. Galvanisierungslösung

10. Galvanisierungsbedingungen: Stromdichte, Galvanisierungsimpuls

11. Temperatur

12. Luftfeuchtigkeit

13. Zeit

① Gründe für das einfache Wachstum von Zinnwhiskern:

1. Helles Zinn ist leicht zu züchten Zinn Whisker

2-1. Die Oberfläche von reinem Zinn ist anfällig für natürliches Kristallwachstum

2-2. Je höher die Reinheit des Zinns, desto größer ist die Wahrscheinlichkeit der Bildung von Zinnwhiskern

3. Chemischer Stress ist die wichtigste Triebkraft für das spontane Wachstum von Zinnwhiskern

② Definition des Zinnwhiskers:

A. Länge >10 µm

B. Konsistente Querschnittsform

C. Es gibt Gräber und Hörner

D. Längen-/Breitenverhältnis >2

E. Es ist gestreift

3. Methode zur Berechnung der Länge von Zinnwhiskern:

A. JEDEC-22A121 Messmethode

B. JEDEC-201&IEC-Messmethode

④ Längenbeschränkung für Zinnwhisker:

<25 um, <30 um, <45 um, <50 um, <60umJESD201 Die Anforderungen an die Länge des Zinnwhiskers sind je nach Testmethode unterschiedlich.

(2) Die Hemmung oder Reduzierung von Zinnwhiskern kann auf 9 Arten erfolgen

1. Fügen Sie eine Barriereschicht, z. B. eine Nickelschicht, zwischen Kupfer und Zinn hinzu

2. Kupfer → Nickel → Palladium → Gold (bildet eine Sperrschicht)

3. Verwenden Sie einen Nickel-Palladium-Leadframe

4. Nebelbeschichtetes Zinn (5 µm)

5. Verzinnung (10µm)

6-1. Sprühverzinnung oder Verzinnung (8~12 µm) innerhalb von 24 Stunden, Abschrecken (Glühen) Feuer (150 ℃) 1~2 Stunden (Trocknungsbehandlung

Nach dem Backen)

6-2. Verzinnung (>7,5 µm) + Nachtrocknung

7. Erhöhen Sie den Silbergehalt bei der Verzinnung

8. Die Temperaturbelastung beim Schweißen sollte möglichst gering sein

9. Reduzieren Sie den Kupfergehalt von reinem Zinn oder die Exposition gegenüber Kupfer

(3) Einführung der Zinnwhisker-Testmethode:

① Lagerung bei Raumtemperatur:

1. Büroraumtemperatur, 1000h

2. 20~25℃/30~80%RH, 1500h, 4230h

② Lagerung bei hohen Temperaturen:

1. 55℃/2 Jahre, 3400h

2. 90℃/400h

③ Temperatur- und Feuchtigkeitslagerung:

1. 50 °C/85 % relative Luftfeuchtigkeit, 1500 h

2. 51 °C/85 % relative Luftfeuchtigkeit, 3000 h

3. 55 °C/80 – 95 % relative Luftfeuchtigkeit, 4230 h

4. 55 °C/85 % relative Luftfeuchtigkeit, 2000 h, 4000 h (1000 h einmal prüfen)

5. 60 °C/85 % relative Luftfeuchtigkeit, 4000 h

6. 60 °C/87 % relative Luftfeuchtigkeit, 3000 h

7. 60 °C/90 ± 5 % relative Luftfeuchtigkeit, 3000 h

8. 60±5℃/93 (+2/-3) %RH, 1000h, 4000h

9. 60 °C/95 % relative Luftfeuchtigkeit, 1000 h, 1500 h

10. 85 °C/85 % relative Luftfeuchtigkeit, 500 ± 4 Stunden

④ Temperaturschock (TST):

1. -55 (+0/-10) ℃ ←→ 85 (+10/-0) ℃, 20 Min./1 Zyklus, 1500 Zyklen (einmal für 500 Zyklen prüfen)

2. 85 ± 5 °C ←→ 40 (+5/-15) °C, 20 Min./1 Zyklus, 500 Zyklen

3. -35±5℃←→125±5℃, Verweilzeit 7min, 500±4 Zyklen

4. -55 (+0/-10) ℃ ←→ 80 (+10/-0) ℃, 7 Minuten bleiben, 20 Minuten/1 Zyklus, 1000 Zyklen

⑤ Temperaturzyklus (RAMP):

1. -40 °C (30 Min.) ←→ 85 °C (30 Min.), RAMPE: 5 °C/Min.), 2000 Zyklen

2. -40 °C (15 Min.) ←→125 °C (15 Min.), RAMPE: 11 °C/Min.), 500 Zyklen

3. -40 °C (15 Min.) ←→125 °C (15 Min.), RAMPE: 15 °C/Min.), 54290 Zyklen

(4) Prüfmittel:

A. Prüfkammer mit konstanter Temperatur und Luftfeuchtigkeit

B. Temperaturschock-Testkammer

C. Temperaturzyklus-Testkammer